Hello

For a while now I’m looking for a solution to repair the body of the Velox. But it is really not easy to find someone to straighten sheet metal, nowadays nobody knows how anymore. I would have to look at vintage car restorers, but I have no time search. So I decided that once again I’ll manage by myself. After all, often it is fear of failure that hinders initiative. Fear does not take away danger so let’s go!

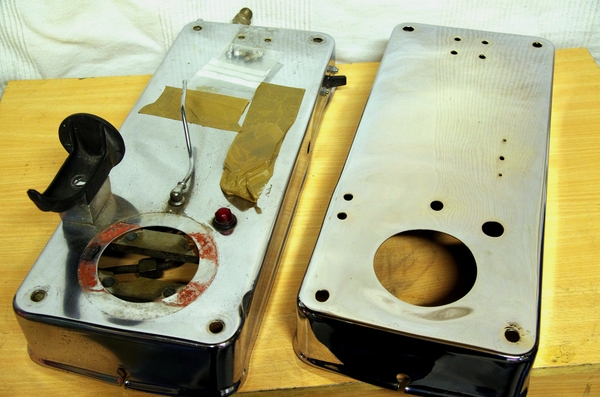

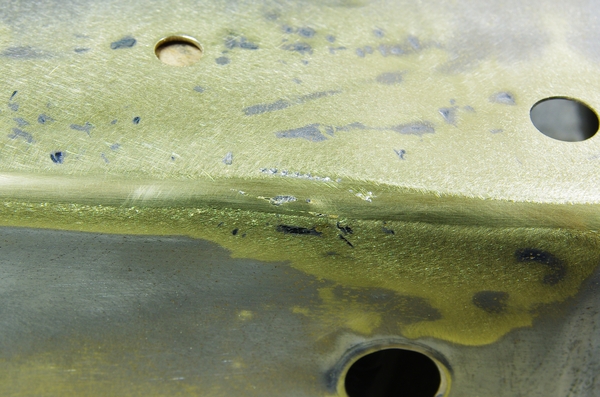

On this picture we see various problems, there are these wide curves like waves. And there is this fold just above the water inlet valve on the right. Curves taken by the sheet at the moment of impact will be very simple to fix. Clamps, wooden blocks, anything that comes to hand and will perform the necessary effort to restore its original shape. It only took about thirty minutes, it was impressive but finally was nothing. The real challenge will start immediately after. The small fold in the corner and various small defects in material will be much more complicated to fix. It is brass that will have re chrome, so impossible to use putty as you might do on a painted surface.

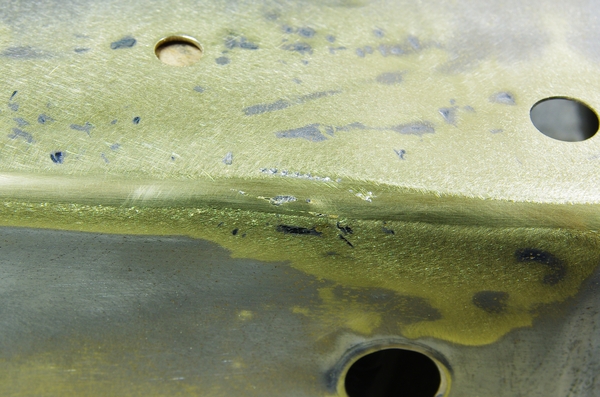

One can’t see really well on pictures but the defect in angle is still important. Really not easy to restore its original shape to this fold. I modified a little tool I shaped into rounded at its end. Then gradually hitting from inside I got to remove quite all traces.

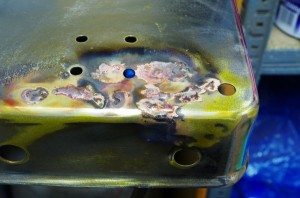

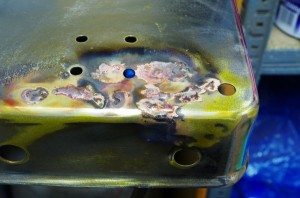

First try to fill the remaining impacts by welding. This is not a good solution because the metal works hard due to high temp and finally it tends to exacerbate the problem.

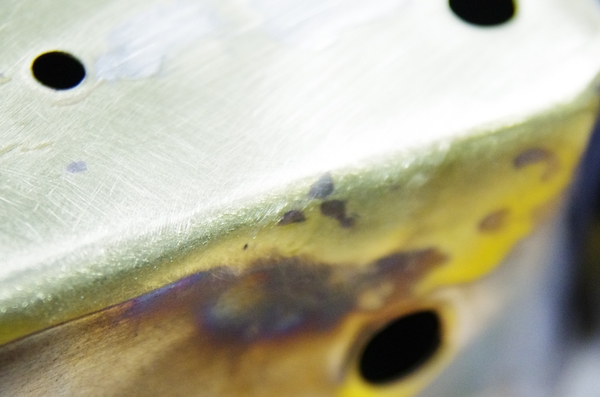

Finally I removed almost everything. Second try, this time with solder. Plumber’s tin, it melts at a lower temperature. This is more efficient but it is still not ideal.

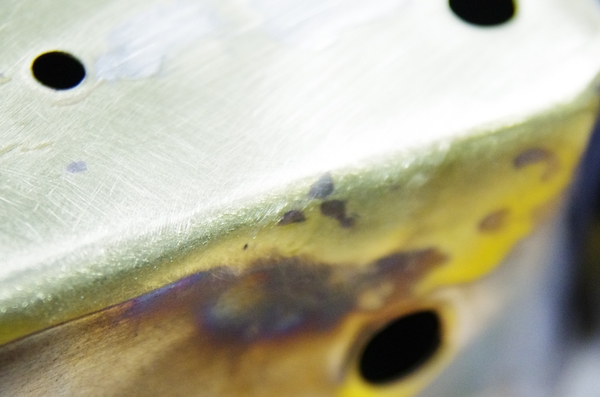

Finally there won’t be no quick fix, it will take time but it will be better I think, gradually completely fix all remaining small defects. Pushing from the rear bodywork with a hammer while resting on a flat and hard surface. That’s all for now. To follow after Christmas days. For now this view of the Velox enjoy me better than what I found opening the package the first time.

Wish you all merry Christmas days, and great year’s end.

Pascal

Pascal